Turn-key complete lines for the wire and cable manufacturers.

European quality, made in Spain.

From drawing to take-up, at Tecnocable Machinery we design and manufacture industrial equipment for the production of electrical cable, telecommunications cable, and metal conductors. We offer complete, customized solutions manufactured in Spain, backed by global technical support.

We manufacture complete machinery lines for cable production.

European quality, made in Spain.

From drawing to take-up, at Tecnocable Machinery we design and manufacture industrial equipment for the production of electrical cable, telecommunications cable, and metal conductors. We offer complete, customized solutions manufactured in Spain, backed by global technical support.

Three decades of engineering

Over 30 years manufacturing cable machinery in Europe. Trusted by 47+ plants across 12 countries. Critical spare parts supported by Powered by Grupo Zamec.

Fast delivery spare parts, critical stock in Spain

Over 30 years manufacturing cable machinery in Europe. Trusted by 47+ plants across 12 countries. Critical spare parts supported by

Powered by Grupo Zamec.

Genuine customization, not rigid catalogs

Need a faster drawing machine, an extruder for a new polymer, or a special rod breakdown unit?

We make it happen.

Custom engineering directly from the manufacturer.

OEE and TCO as machine design guidelines

Each line is engineered for maximum process efficiency.

Less scrap, reduced downtimes, better kWh/kg consumption.

Verifiable results.

Solutions and product lines

Unique provider for the entire cable manufacturing process

We provide modular lines and equipment for the four key phases of the process, with full integration and performance control.

TECNOCABLE MACHINES

From start to finish cable production solutions

Our machinery covers the entire process, from raw material handling and cabling to extrusion and final processing with standard equipment.

Wire Drawing machines

Robust, versatile wire drawing machines optimised for demanding production environments, ensuring continuous and stable operation.

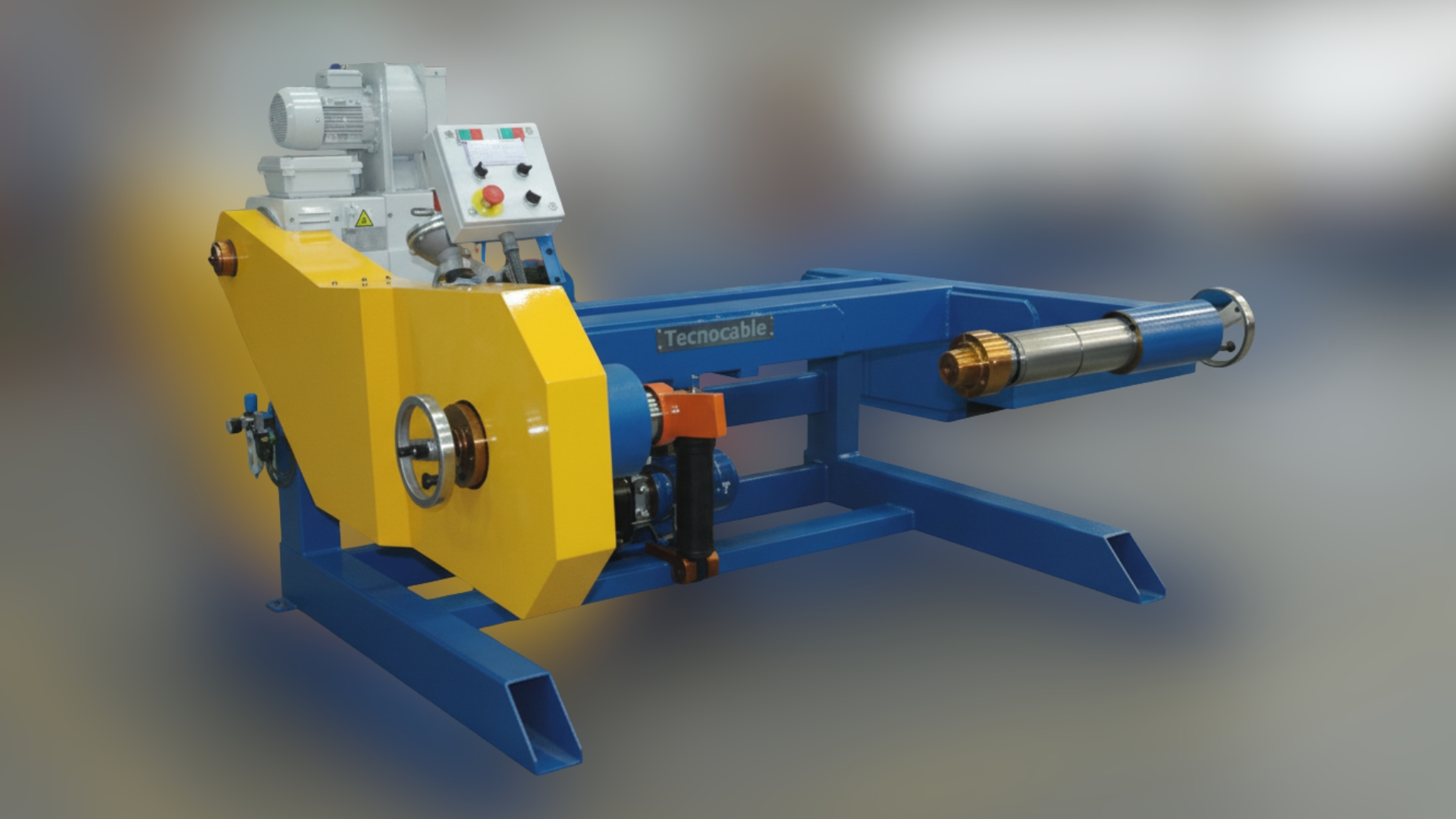

Rod Breakdown Machines

Wire rod preparation: removal of impurities with high robustness and low maintenance.

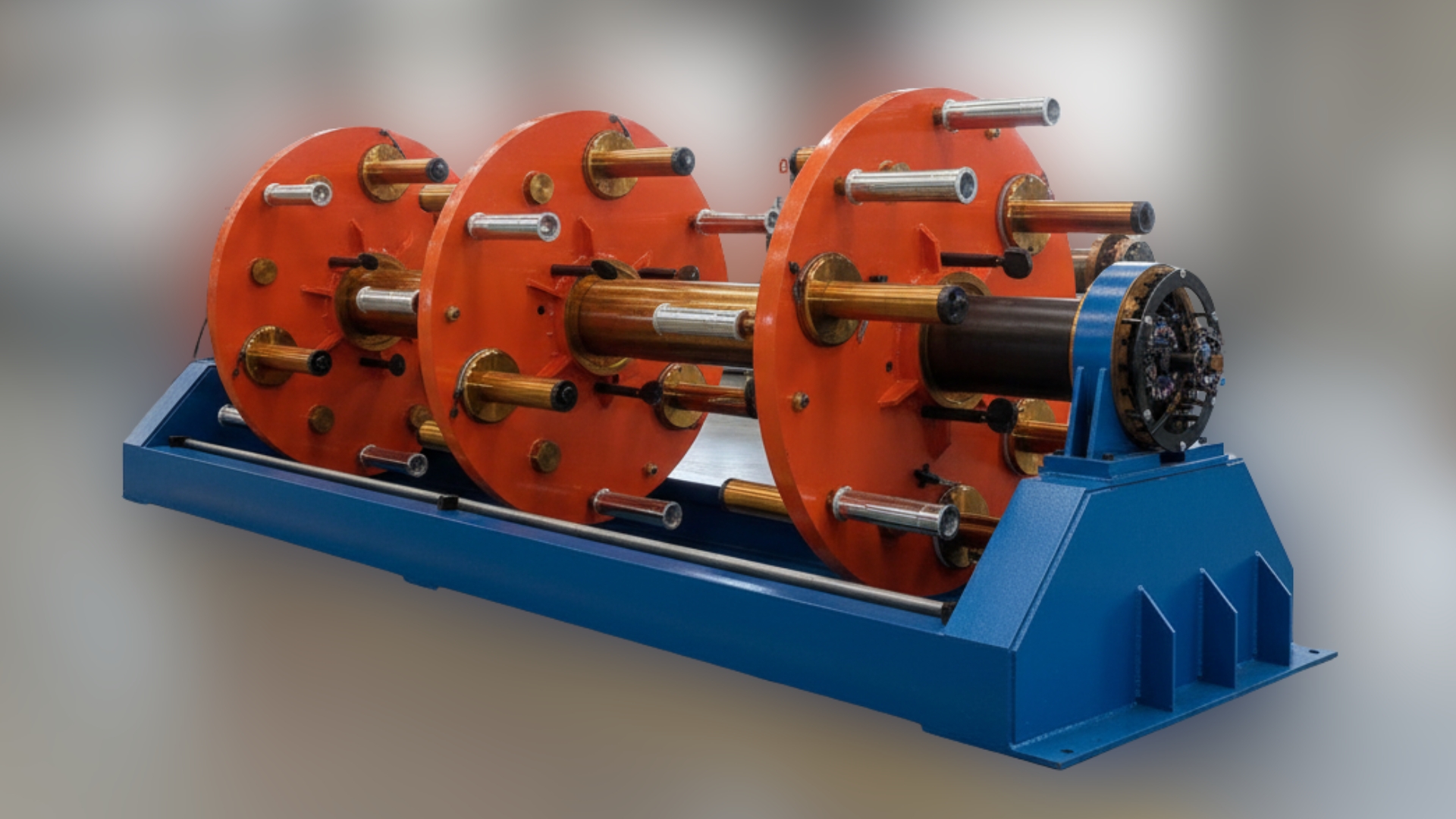

Cable Laying and Stranding

We combine advanced technology, productivity, and robustness, ensuring precise twisting and continuous production.

Rigid Strander

We combine advanced technology, productivity, and robustness, ensuring precise twisting and continuous production

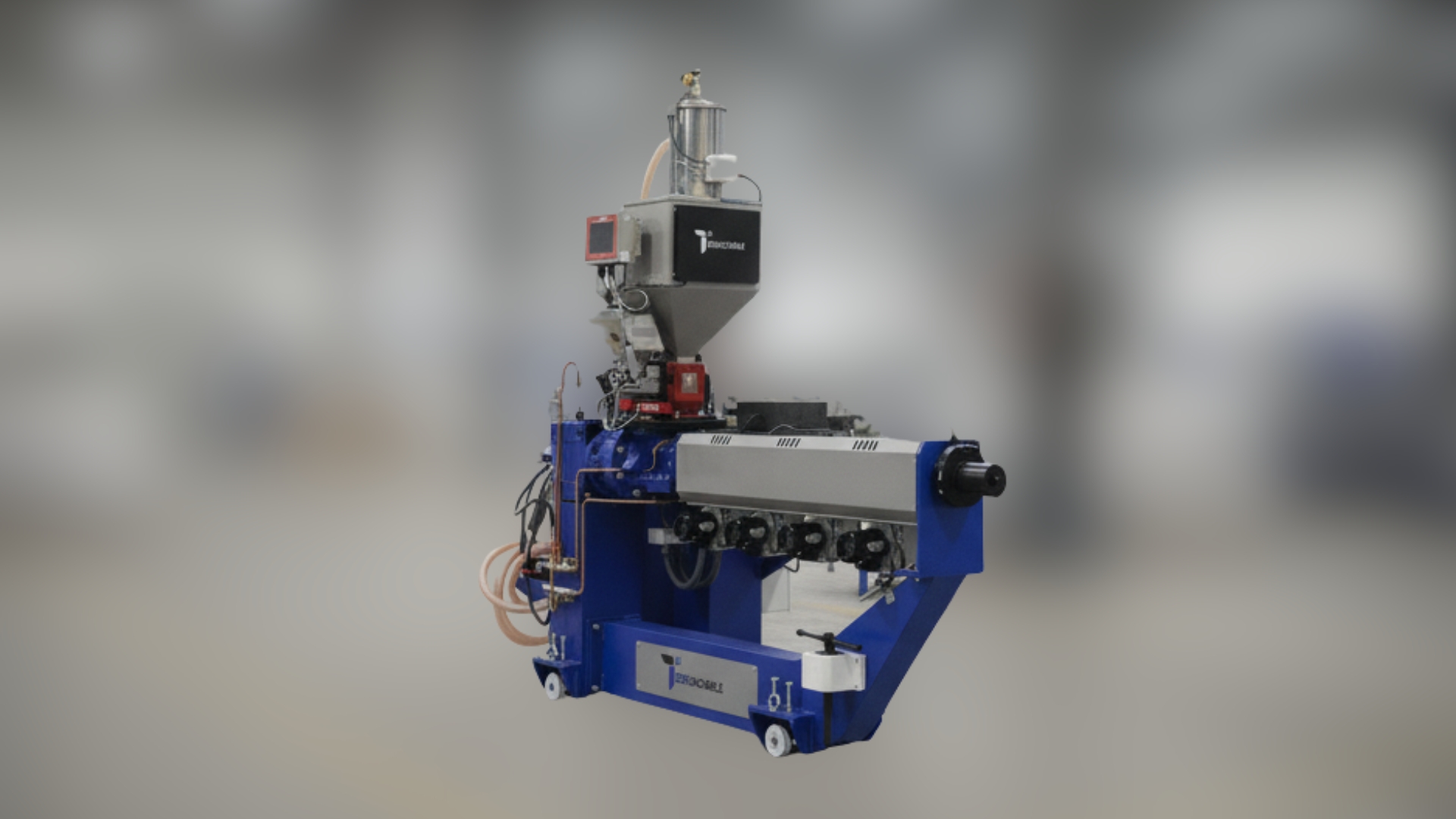

Extrusion

Robust, efficient, and adaptable machines, capable of processing multiple materials with precision, reliability, and maximum productivity.

Coilers

Vertical-axis automatic coilers, designed to adapt to different cable formats and production requirements.

Spoolers

These systems ensure efficient, stable, and adaptable take-upfor different cable types

Pay-offs

We offer static, column-type, and motorized versions, with pneumatic or manual pintles.

Extrusion Heads

Manufactured in nitrided treated steel with a compact design, our extrusion heads ensure durability and uniformity.

Auxiliary Equipment

With reinforced structure and high-quality components, our auxiliary solutions ensure efficient, stable, and adaptable operation

WHAT YOU CAN EXPECT

Typical ranges depending on solution scope and product mix. Verifiable with references.

of scrap reduction,

depending on line and cable type

of productivity increase,

depending on optimization

of energy consumption reduction, depending on process efficiency

of unplanned downtimes,

thanks to predictive maintenance

to achieve the typical ROI,

depending on scale and product mix

of spare parts availability lead time, thanks to Grupo Zamec

of setup time savings and configuration changeovers

of customer satisfaction (according to an independent annual survey)

We operate under the UNE-EN ISO 9001:2015 quality management system to deliver our products worldwide.

WHY CHOSING TECNOCABLE

Certified manufacturing

100% production in Spain under ISO 9001:2015. Controlled quality and European standards in every machine.

Integration with Zamec

Thanks to Zamec, we manufacture our own parts and spare components to provide speed, reliability, and full control.

Customized solutions

We design machinery adapted to the specific needs of each plant and production process.

Agile support

Direct and fast technical support, with active presence in Central Europe, Northern Europe, and LATAM.

Over 100 years

Experience accumulated since 1914 in drawing, cabling, and extrusion: a legacy of precision and reliability.

Global reach

Clients and partners in more than 16 countries. Local presence with an international cooperation.

The strengths of working with Tecnocable

European engineering

Robust design, reliability

and regulatory compliance.

Performance and OEE

More productivity, less scrap

and optimized consumption.

Close maintenance support

In-house assistance and rapid spare parts delivery

thanks to Zamec.

International network

Network of agents and plant commissioning technicians.

+100 years of engineering and innovation

Since 1914, FISAM has been a leader in the development of wire drawing, extrusion and cable machinery, driving technological evolution in the sector in Europe. After decades of innovation and collaboration with TECNOCABLE and ZAMEC, today we combine experience and vision to offer complete production lines with precision and innovation at the service of industry.