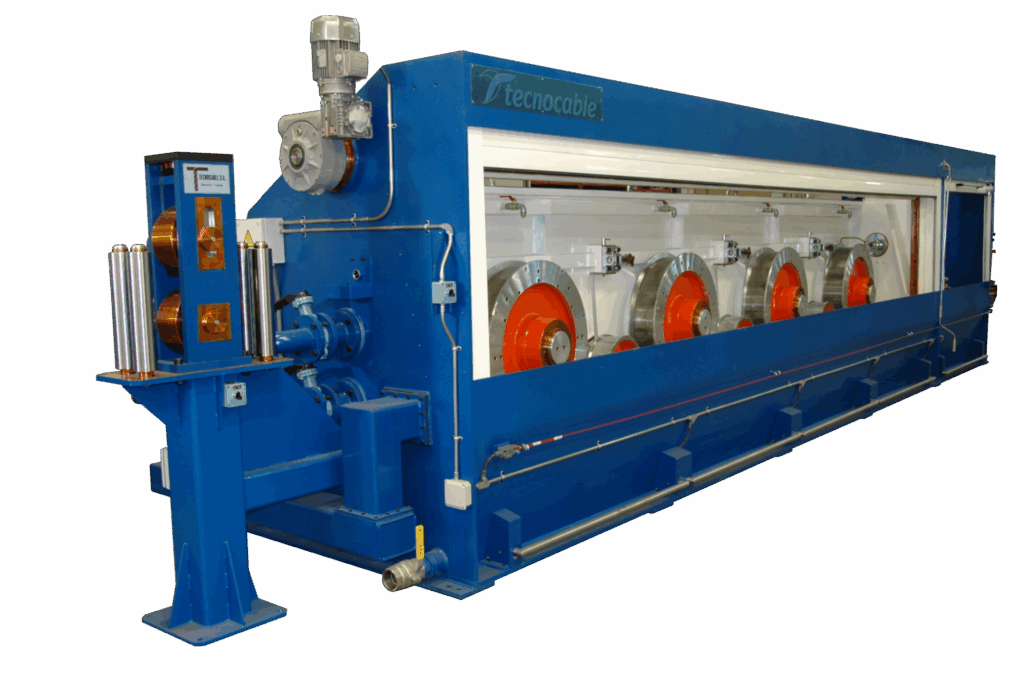

Rod Breakdown Machines

Our rod breakdown machines are designed to reduce wire diameter in a controlled and continuous way, ensuring an optimal surface condition for subsequent processes such as wire drawing or extrusion.

Since 1914, we have been manufacturing machines tailored to the specific requirements of each project, delivering reliable, efficient, and long-lasting performance.

LESS CONSUMPTION. MORE CONTROL. HIGHER PERFORMANCE.

Adapted rod breakdown solutions

High-performance annealing furnaces

- Capacity up to 9,000 A

- Simultaneous processing of up to two wires

- Uniform and stable annealing, even at high speeds

Drawing speed of up to 40 m/s

- Optimization of production time

- Smooth and consistent processes without interruptions

Process-optimized elongation

- Improved yarn behavior during wire drawing

- Reduced mechanical wear and operational savings

Versions with dual or multi-engine engines

- Always equipped with high-efficiency motors

- Personalized adaptation to the rhythm of each plant

Scalable technology: from single-wire to double-wire operation

- Capacity adjustable according to production volume

- Ideal for both compact lines and large installations

Wire diameters from 1 mm to 6 mm

- Total flexibility for different applications and needs

Committed to quality and efficiency

Each rod breakdown machine is built using high-strength materials and precise manufacturing standards to ensure stability, durability, and consistent breakdown quality.

Our experience, combined with a flexible and customized approach, allows us to deliver solutions that provide real and sustainable value to your production line.

Do you need a rod breakdown line adapted to your production?

At Tecnocable, we do more than supply standard machines: we design solutions tailored to each customer.

Contact us, and we will help you develop the ideal solution for your industrial process.