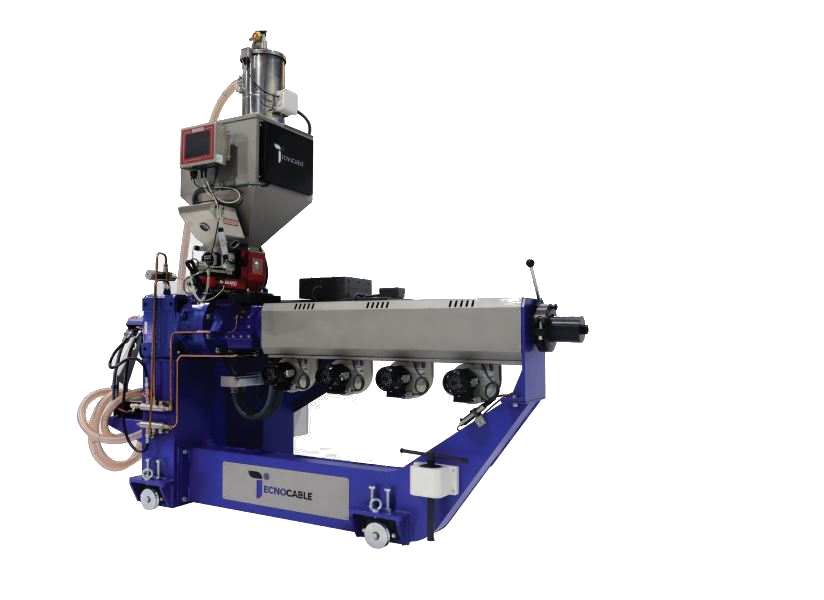

At TECNOCABLE, we develop industrial extruders that are custom-designed to meet the technical, production and operational requirements of each customer. Our extrusion lines are present in factories around the world, from simple applications for domestic cables to complex vulcanisation or tandem extrusion lines for the automotive, telecommunications and energy industries.

Our commitment is clear: to offer robust, efficient and adaptable machines capable of processing multiple materials with precision, reliability and maximum productivity.

Customised extrusion solutions

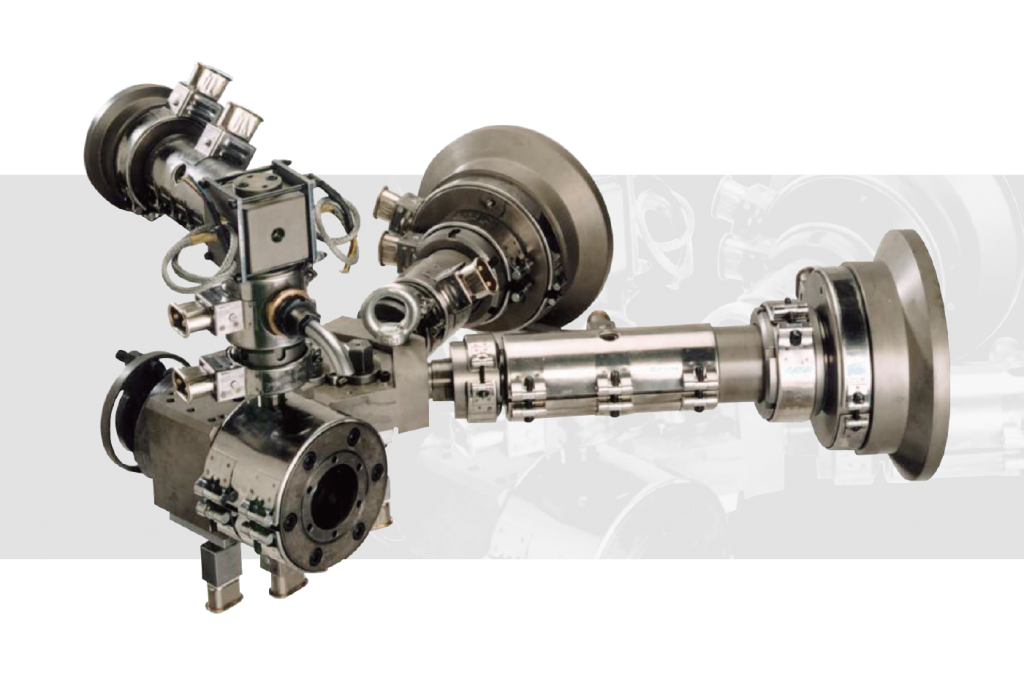

- Extruders for coating, insulation, and sheathing

- Lines for domestic, data, automotive and power applications cables

- Tandem lines for filling and sheathing

- CV systems for insulation and coverings

- Water-cooled feeding zones

- Optimized temperature and pressure control by zone

- Integration with controllers, drives, spoolers, and accumulators

Benefits of Tecnocable extruders

- Customised design: we adapt the line to your production objectives

- In-house engineering: complete technical development at our facilities

- High productivity: stable, continuous and high-speed extrusion

- Material versatility

- Durability: reinforced components to minimise wear and tear

- Integral technical support: installation, training, assistance, and repair

ESP

ENG

Committed to quality and innovation

At TECNOCABLE, we do not just sell standard machines. We study each project in depth to develop an optimised, efficient and durable solution.

Our experience in extrusion lines allows us to handle everything from small single-strand systems to highly complex tandem lines, always maintaining the quality and precision of the process.

Do you require an extruder tailored to your production line?

We specialise in creating solutions tailored to your requirements. Tell us about your process and we will help you define and implement the ideal extrusion line for your objectives.